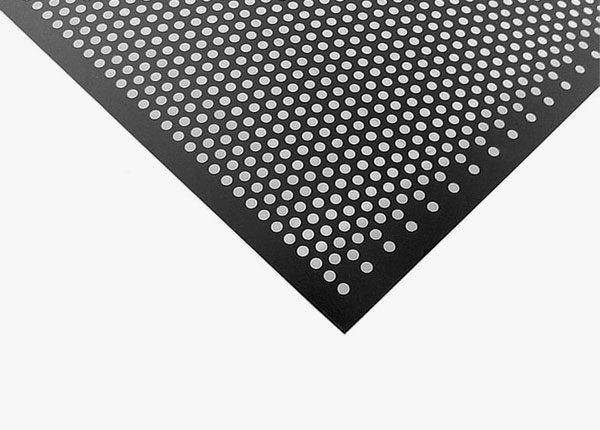

The alloy has similarly adjustments to the mixed titanium and aluminium degrees to make certain top-rated excessive temperature properties. Applications of this Alloy Steel Grade 9 Perforated Plate sencompass: Heat Exchangers and Process Piping, Carburizing Fixtures and Retorts, Furnace Components, Electric Range Heating-Element Sheathing, Extruded Tubing for Ethylene and Steam Methane Reforming Furnaces, Ammonia Effluent Coolers, etc.These alloys are categorised as terrific alloys and showcase splendid corrosion resistance and excessive strength. They are specially made to withstand decided on reagents. These alloys are able to functioning even at excessive temperatures. It is known for its splendid corrosion resistance in chemical environments that incorporate sulphuric acid, chlorides, phosphoric acid and nitric acid. It is straightforward to manufacture Alloy Steel Grade 9Perforated Sheets alloy to shape blending tanks, heat exchangers, pickling system etc. It may be welded via way of means of shielded steel arc welding, gas tungsten arc welding and gas steel arc welding. It may be warm worked at temperature stages of 760 Degree C - 1175 Degree C (1400 Degree F - 2150 Degree F). It ought to be annealed at 982 Degree C – 1010 Degree C (1800 Degree F – 1850 Degree F) for time commensurate with phase length. They are composed of nickel-chromium-iron because the number one elements.

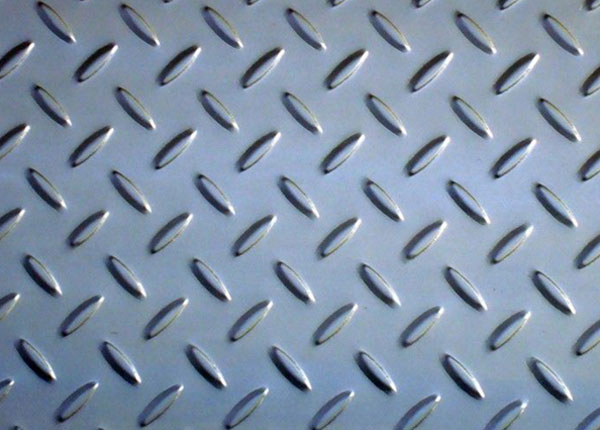

Alloy Steel Grade 9 Slatting Plates is used within the following applications: Produce blending tanks, heat exchangers, valves, fittings and fasteners; Production of gasoline, solvents, explosives and natural chemicals; Pharmaceuticals and food industry. Additives which can be used on this alloy to decorate its strength, corrosion resistance encompass molybdenum, copper and nitrogen. These alloys are categorised as terrific alloys because of their excessive strength and ability to feature at excessive temperatures. It belongs to the austenitic stainless steel organization and is proof against numerous corrosive environments. The aggregate of chromium and molybdenum make this alloy proof against each oxidizing and decreasing acids and salts.