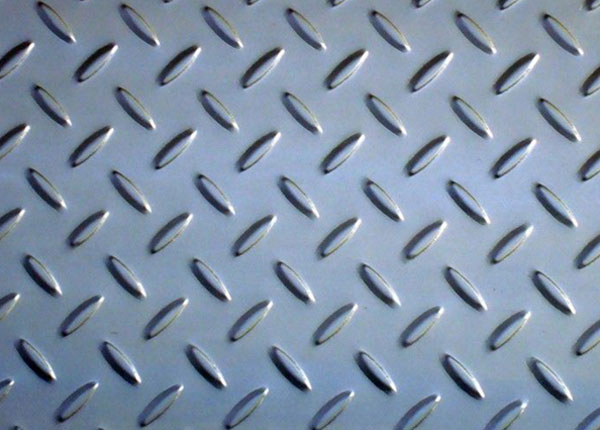

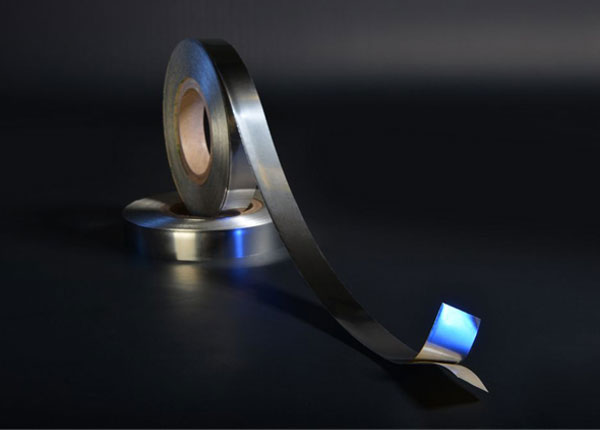

In the assessment of materials for exhaust valve applications, these Alloy Steel Grade 5 Slatting Sheets have completed properly in a 1675 Degree F (913 Degree C) lead oxide screening test. It time and again provided right outcomes, with corrosion rates. Like different nickel-chromium alloys, it additionally resists assault via way of means of different exhaust circulate impurities which include sulphur, bromine and chlorine. It has splendid warm hardness. The warm working variety for this alloy is 1800 Degree F – 2200 Degree F (980 Degree C - 1205 Degree C). It may be joined via way of means of the flash welding tactics generally utilized in valve manufacture.This Alloy Steel Grade 5 Slatting Plates ought to be reheated to 2200 Degree F (1205 Degree C) on every occasion its temperature falls underneath 1800 Degree F (980 Degree C). This short-time heat remedy has been determined to produce material with the top-rated aggregate of properties regular with economy. Longer, extra complicated, getting older remedies can be used to enhance specific properties required for particular applications.The great process is to system with barely oversize, precipitation heat treat, then end to length. A mild everlasting contraction takes location all through precipitation.

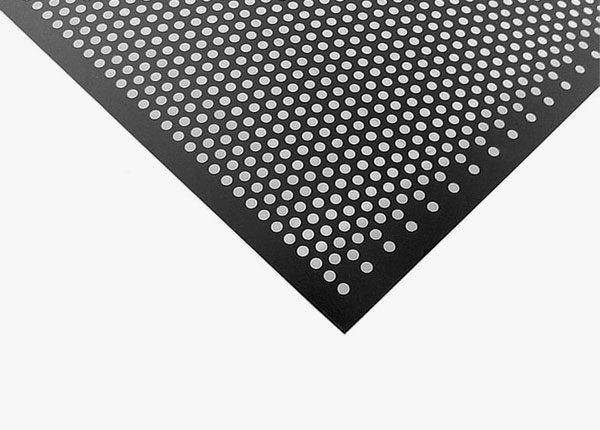

Precipitation dealt with material may be end machined to high-quality finishes and near tolerances, and could have right dimensional balance. This alloy also can be inertia welded. The principal gain of many of these Alloy Steel Grade 5 Perforated Sheets changed into that they now ought no longer to be heat dealt with after welding to repair the corrosion resistance.This alloy is twin licensed and combines the properties of each form. It is an iron-nickel-chromium alloy having the incredible primary composition, by means of having drastically better creep rupture strength. The better strength outcomes from near manipulate of carbon, aluminium and titanium contents together with an excessive temp anneal. The alloy's change changed into to manipulate carbon and grain length to optimize strain rupture properties.