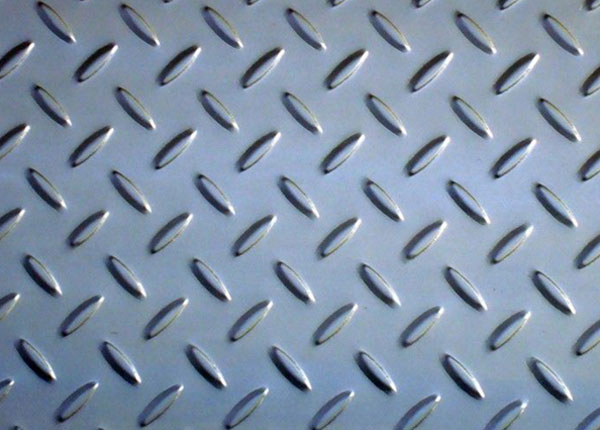

Cold rolling can be finished at the alloy after annealing. Alloy Steel Grade 11 Slatting Sheets is likewise used within the following applications: Chemical and petrochemical processing industry; Downhole carrier in deep sour gas wells; etc.They are terrific alloys having nickel because the base steel. They are composed of nickel-chromium-iron because the main elements. Additives which include molybdenum, copper, and nitrogen are delivered so as to decorate the corrosion resistance and strength of these alloys. These alloys can feature effectively even at increased temperatures. It is an alloy comprising of nickel-iron-chromium by means of having a silicon as an additive. Using silicon as an additive offers the alloy better oxidation resistance. This Alloy Steel Grade 11Slatting Platesis known for its right strength at excessive temperatures and right resistance to oxidation and discount environments. The microstructure of the alloy continues its balance even after being uncovered to excessive temperatures for lengthy durations. It is used within the following applications: Industrial heating; Furnaces, muffles, retorts and conveyor systems; Heat treating baskets and fixtures; etc.Corrosion resistance of the alloy may be better and prolonged over some of environments via way of means of including metals like molybdenum, copper, nitrogen, etc.

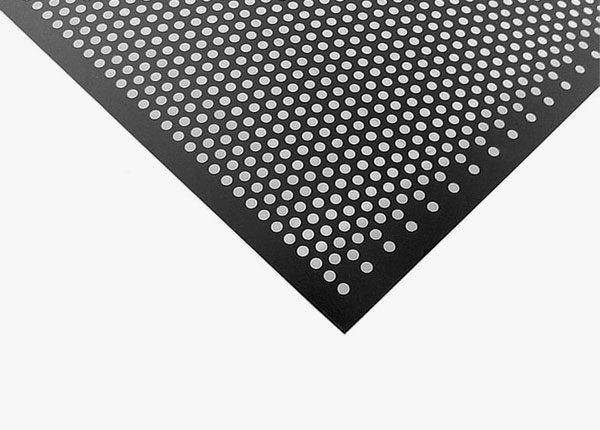

This alloy has right strength over excessive temperatures. Alloy Steel Grade 11 Perforated Sheets is an alloy comprising of iron-nickel and chromium, with an excessive nickel and chromium content material in comparison to different alloys. This alloy proves to be a cost powerful opportunity for changing different alloys which can be utilized in corrosive decreasing, oxidizing and sulfurizing environments. The alloy additionally is known for its right strain-rupture strength at excessive temperatures. Some of the standard kinds of the alloy are pipes, welds, tubes, plate, strip, round, squares and forged fittings.It is used within the following applications: Petrochemical, chemical and thermal processes; ID finned pyrolysis; Tubing of excessive-severity ethylene furnaces; etc.