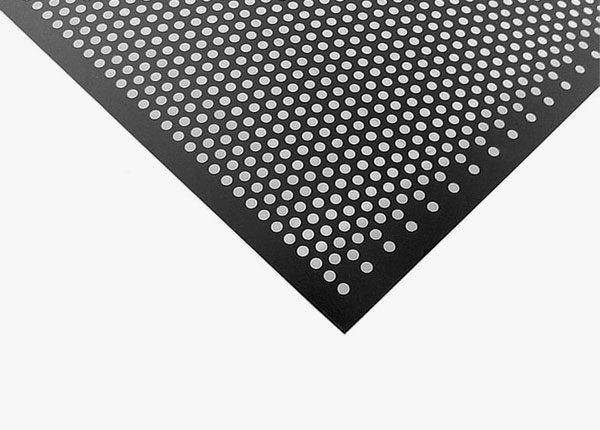

And so, Alloy Steel Grade 12 Perforated Plates has an excessive nickel content material, enough to withstand chloride ion strain corrosion cracking, and a totally strong austenite structure. The degrees of molybdenum and copper permit the alloy to withstand decreasing dealers and acids. Chromium offers resistance to oxidising situations, along with nitric acid solutions, nitrates and oxidising salts. The alloy is titanium stabilised to withstand pitting and intergranular assault after fabrication, especially welding, which includes heating within the essential sensitisation temperature variety (650 Degree C – 760 Degree C). Alloy Steel Grade 12Perforated Sheets gives fantastic resistance to corrosion via way of means of sulphuric and phosphoric acids and is frequently the maximum cost powerful alloy in sulphuric acid service.Applications of this alloy include: Sulphuric Acid Piping and Cessels; Phosphoric Acid Evaporators; Pickling Tank Heaters, Pickling Tanks and Equipment; Chemical Process Equipment; Propellor Shafts; Tank Trucks; Calorifiers; Electrostatic Precipitator Electrodes; Hot Vessels for Food, Water and Seawater; Ammonium Sulphate Vessels; Expansion Bellows; Marine Exhaust Systems; Power Station Ash Hoppers; etc.It is an alloy that has excessive tensile energy, fatigue crack boom resistance, proper weldability, metallurgical balance and ductility, excessive fracture and effect toughness, low coefficient of thermal growth, and resistance to oxygen embrittlement, which allows hot fabrication without cracking.

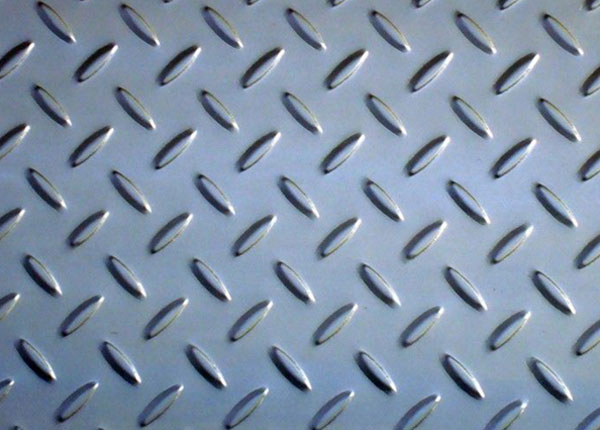

The following are the listing of applications of this Alloy Steel Grade 12 Slatting Plates: Prototype fusion reactors, and High-energy cryogenic applications.They encompass some of factors in one-of-a-kind combos to gain the favoured result. They also are called excessive overall performance alloys, and are to be had in one-of-a-kind shapes. They may be strengthened via way of means of work hardening, precipitation hardening, and solid-solution hardening. It has excessive energy and coffee thermal growth coefficient at temperatures as much as 800 Degree F.It may be machined the usage of traditional machining techniques that are used for iron-primarily based totally alloys. Machining operations are finished the usage of commercial coolants.