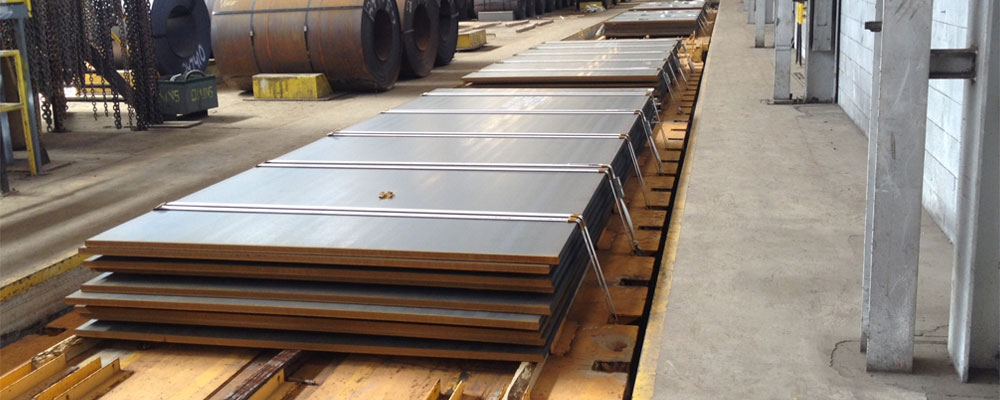

High-pace operations along with grinding, milling or turning, are finished the usage of water-base coolants. Alloy Steel Grade 22 Slatting Sheets is welded the usage of gas-tungsten arc welding, shielded metallic-arc welding, gas metallic-arc welding, and submerged-arc welding techniques. It is heat dealt with via way of means of annealing at 983 Degree C (1800 Degree F). It is solid at 927 Degree C to 1149 Degree C (1700 to 2100 Degree F). It is hot worked at 885 Degree C to1149 Degree C (1650 Degree F to 2100 Degree F). It is cold worked the usage of standard tooling. Annealing of this alloy is completed at 983 Degree C (1800 Degree F) accompanied via way of means of cooling in air. It is aged at 719 Degree C (1325 Degree F) for eight h accompanied via way of means of cooling to acquire most tensile properties. Alloy Steel Grade 22Slatting Platesis likewise aged at 774 Degree C (1425 Degree F) for 12 h accompanied via way of means of cooling to acquire most hot rupture energy. It is an excessive-energy, corrosion-resistant alloy that has progressed resistance to chloride brought on strain corrosion cracking because of its excessive nickel content material. They are used significantly due to their corrosion resistance, excessive temperature energy and their unique magnetic and thermal growth properties.

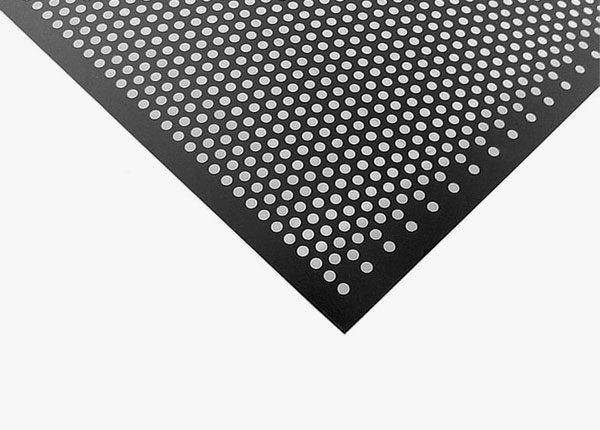

The molybdenum content material in its composition aids resistance to pitting and crevice corrosion. In addition, nickel with copper and molybdenum awesome resistance to trendy corrosion in decreasing media. The following are the listing of applications of this Alloy Steel Grade 22 Perforated Sheet Marine and pump shafting; Fasteners; Tubular products and valves; Landing nipples, device joints and packers; High-energy piping systems; etc.The majority of the steels include certain percentage of nickel. In all instances it is the aggregate of chromium with the nickel that does the job.It is used within the following applications: Gas turbine seals, Casings, and Glass to metallic sealing.