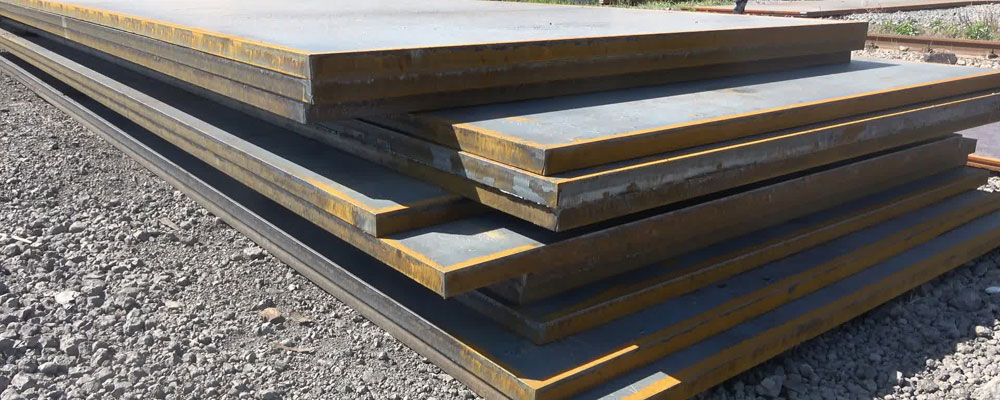

This technique is appropriate for positioning and fillet kind welds. Suitable filler wires of this EN8 Carbon Steel Platesfor distinctive steel joints to nickel-base alloys and matching composition wires for welding to austenitic steels. For becoming a member of the alloy to itself an alloy cord is suggested in which excessive-temperature oxidation resistance is needed within the weld. The most powerful joints are produced via way of means of approaches with excessive power density which includes laser and electron beam welding. If it is not possible to keep away from quite restricted joint designs, post-weld strain relieving in Carbon Steel 080M40 Plates must be finished as quickly as conceivable to keep away from not on time strain cracking. A remedy of two hours at 1100 Degree C (2010 Degree F) in air observed via way of means of air cooling is suggested. The identical cycle can also additionally function a pre-oxidation remedy supplied the surface is wiped clean of lubricants and different contaminants.

Brazing, diffusion bonding and brief liquid segment bonding (TLP) are feasible if intense care is first taken to do away with the protecting alumina film via way of means of grinding. For maximum strength at excessive temperatures, mechanical joints which include matching composition rivets, pins and threaded connections are regularly used.The nature of this EN8 Steel Plates calls for care in excessive strain rate forming operations which include bending, deep drawing, punching and shearing. For excessive deformations it is encouraged that the material and tooling is warmed to 150 Degree C - 200 Degree C (300 Degree F - 400 Degree F). Stronger than natural nickel, these alloys are immune to corrosion through many agents, along with hastily flowing seawater.