This listing is a long way from exhaustive and enquiries have to be made for specialized excessive temperature or corrosive situations. All metals ‘creep’ beneath strain at excessive temperature and of their synthetic form, additives may also deform. This deformation should motive failure. This makes Carbon Steel ASME SA515 Grade 60 Plates perfect for such components as blades and disks in gas turbine engines. The material however, should decide the predicted lifestyles of every element and use the precise creep and rupture energy within the design.There are a collection of nickel-iron ‘managed growth’ alloys in which the growth coefficient is low and regular over a number of temperatures. TheseASTM A515 Carbon Steel Grade 60 Platesalso are used in which a metallic/glass seal is needed. This alloy has an growth co-green designed to in shape that of soda-lime and smooth lead glasses and therefore affords a valid glass/metallic seal in order to now no longer crack due to differential growth among the two materials.

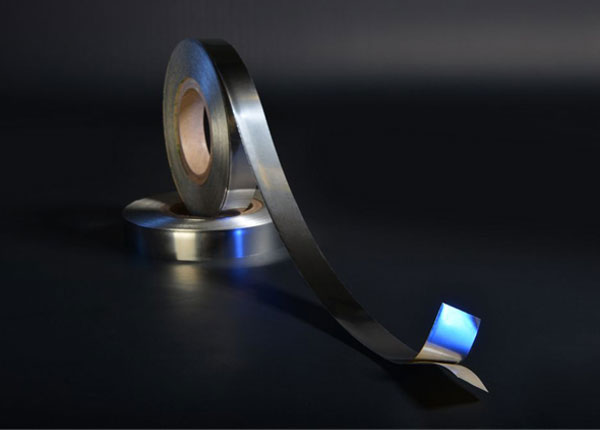

There is a demand for such ASME SA515 Carbon Steel Grade 60 Plates by means of having an excessive magnetic permeability to minimise the energy necessities to generate a sturdy magnetic field, along with that required in tape recorder heads and for magnetic protective round precision cathode ray show devices. These excessive permeability materials are complicated alloys primarily based totally on nickel with number composition possibilities. A standard composition might be: nickel with small quantities of molybdenum and/or copper and the stability iron. This is needed in telephone device industries and electric fitters in which a version in permeability might bring about distortion.