This metal is likewise mild in strength by means of having precise resistance to oxidation at extended temperatures for lengthy intervals of time at 1200 Degrees F - 1600 Degrees F. This metal is a solution heat handled and controlled-carbon model in company of having progressed extended temperature properties. It is meant for excessive temperature structural applications. Carbon Steel ASTM A105 Slip On Flanges is a nickel-iron-chromium alloy with excessive strength and excessive resistance to oxidation. In the solution annealed condition, these products have advanced creep and strain rupture properties. This product would not shape the embrittling sigma segment after long term publicity at 1200 Degrees F (649 Degrees C).

This product is being proof against oxidation and carburization in excessive temperature environments. For excessive temperature applications requiring most excellent rupture and creep properties, this product is used. Excellent resistance to chloride strain-corrosion cracking is any other essential characteristic of this ASTM A105 Carbon Steel Socket Weld Flanges. Added Carbon and annealing remedy on this product lets in for better creep and rupture properties above 1100 Degree F (six hundred Degree C). This product is a solution heat handled (2100 Degree F) with progressed extended temperature properties. This product have set the industry standard in excessive-temperature applications requiring most excellent creep and rupture properties.

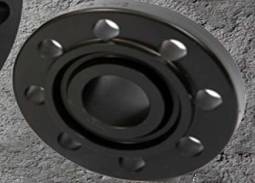

This product is utilized in Chemical industry, Heat treating industry, and Aerospace industry. The better creep-rupture strength of this ASME SA 105 Carbon Steel Forged Flanges is the end result of titanium, aluminium, and carbon contents.The chromium on this product imparts resistance to oxidation and corrosion. This product is utilized in Process Piping and Heat Exchangers. The room temperature strength of this metal is considerably extended with the aid of using precipitation heat remedy. This metal has awesome creep-rupture strength at temperatures to 1300 Degree F (seven-hundred Degree C). This metal has been used for pump shafts, valves, and wellhead additives. This metal is age hardened thru the addition of aluminium and titanium.