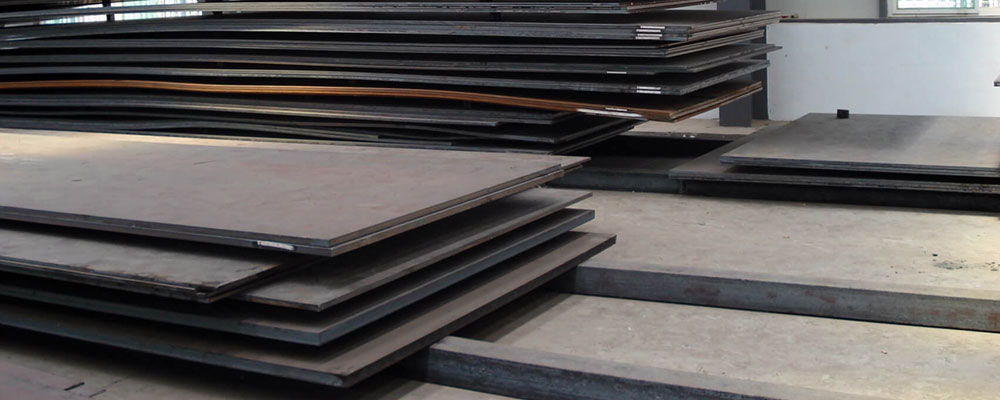

Molybdenum additionally imparts resistance to localized assaults which include crevice corrosion and pitting. Rigid equipment with effective rake angles has to be used so that it will reduce work hardening of the material. There is likewise a demand for materials with a regular permeability over number magnetic flux densities. ASTM A516 Carbon Steel Grade 70 Plates may be comfortably welded via way of means of the gas-tungsten-arc welding and pulsed gas-steel-arc welding approaches. The alloy is annealed 1010 Degree C - 1066 Degree C (1850 Degree F - 1950 Degree F) for half to four h after which water quenched. Following this, the alloy is age-hardened at 704 Degree C - 732 Degree C (1300 Degree F - 1350 Degree F) for 6-8 h and furnace cooled at 26 Degree C - 56 Degree C (50 Degree F - 100 Degree F). The following are the listing of applications of this alloy: Downhole oil and gas applications, Fasteners, High strength piping systems, and Pump shafting.

It is first advanced as an aerospace superalloy and now utilized in quite a number industrial applications, combines first-rate strength and fabricability with tremendous resistance to extended publicity as much as 1300 Degree C (2400 Degree F). Its exceptional properties end result from the mechanical alloying technique via way of means of which it's miles made; a technique which lets in a quality distribution of yttrium oxide debris to be integrated right into a quite corrosion-resistant alloy. This ASME SA516 Carbon Steel Grade 70 Plates has first-rate oxidation resistance as much as 1300 Degree C (2400 Degree F) and full-size creep strength as much as its surprisingly excessive melting factor of 1482 Degree C (2700 Degree F).