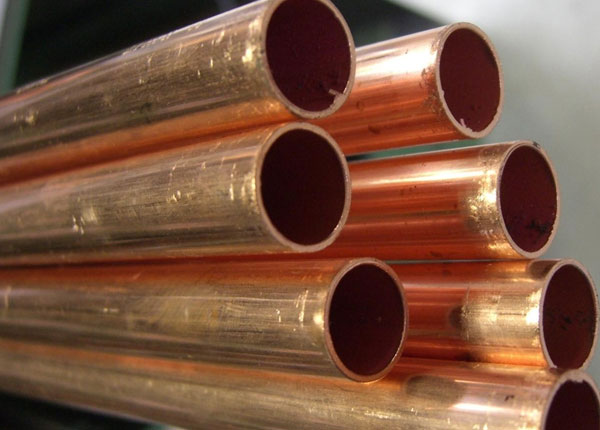

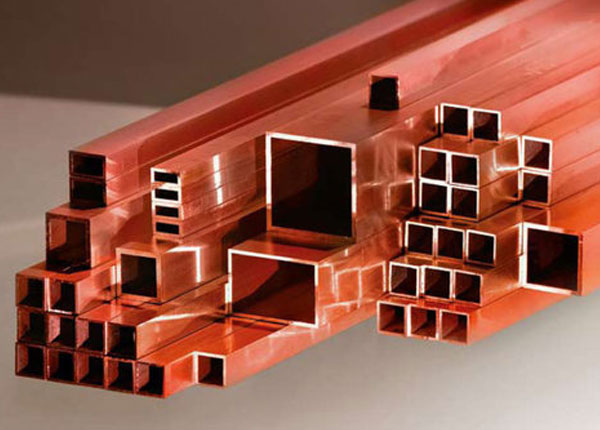

This alloy, with its chromium-nickel content material and coffee carbon, is the maximum flexible and extensively used of the austenitic steels. This alloy has great corrosion resistance in lots of environments and whilst in touch with one-of-a-kind corrosive media. Cupronickel 90 / 10 Welded Tubes has true forming and welding properties in addition to robust corrosion resistance and strength. This alloy is utilized in tanks and boxes for a huge kind of beverages and solids. The decrease carbon content material on this alloy minimizes chromium carbide precipitation because of welding and its susceptibility to inter-granular corrosion. This alloy has better hot strength than carbon; for this reason lots better forging pressures or greater hammer blows are required to forge it. Copper Nickel UNS C70600 EFW Pipes are long lasting and offer great resistance to corrosion and rust. This alloy is utilized in plenty of family and industrial applications. This alloy is the standard metallic this is typically observed in pans and cooking gear. It is utilized in mining and water filtration structures and within the dyeing enterprise. Lower work hardening rate of this product is wanted for cold forging of screws, bolts, and rivets.

This product is extensively greater resistant to solutions of sulphuric acid, chlorides, bromides, iodides and fatty acids at excessive temperature. Tooling and work surfaces of this product have to be very well wiped clean earlier than use. Copper Nickel WNR. 2.0872 ERW Tubes is being extraordinarily difficult and ductile, and are easily fabricated via way of means of old working. Since this product work hardens unexpectedly, in-system annealing can be essential to repair ductility and to decrease hardness. This product are gradual cooled from forging, especially via the temperature variety 1500 Degree F / 900 Degree F (815 Degree C / 480 Degree C). This product is used for Auto mouldings and trim, Wheel covers, Storage tanks, Kitchen equipment / appliances, Electrical enclosures, etc.