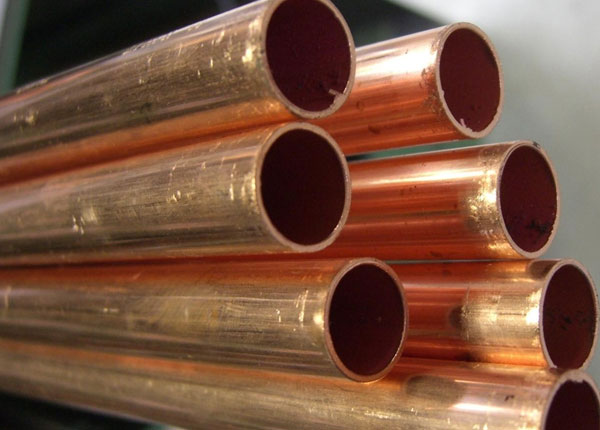

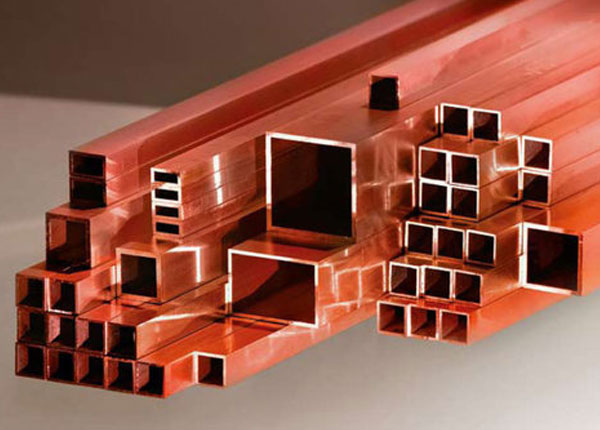

To solution anneal this product, cool unexpectedly in air or water from approximately 1850 Degree F to 2050 Degree F. It has right drawability. Cupronickel 70 / 30 Round Pipes is dominant within the manufacture of drawn stainless components consisting of sinks, hollow-ware and saucepans. This alloy proves to be proof against oxidation, corrosion, and durability. Pitting and crevice corrosion for this alloy can arise in environments containing chlorides, as SCC can arise above 60 Degree C. This alloy may be fashioned into a whole lot of shapes and may be used without annealing, the warmth remedy that softens metals. This alloy is used for procedure system within the mining, chemical, cryogenic, food, dairy and pharmaceutical industries. In a few instances, this Copper Nickel UNS C71500 Square Tubes may be used within the "as-welded" condition. In fact to a few instances as a whole lot as strength is needed to forge this alloy as is needed for carbon and alloy steels. This alloy is the maximum flexible and extensively used austenitic chrome steel within the world, because of its corrosion resistance. This alloy is characterised through mainly low carbon content material even as its chromium and nickel are rather better. Higher machinability wanted for this product, and the decrease corrosion resistance, formability, and weldability are acceptable.

This Copper Nickel WNR 2.9882 Rectangular Pipes containing molybdenum are required within the manufacture of sure prescribed drugs which will keep away from immoderate metal infection. These precautions are vital to keep away from move infection of this product through effortlessly corroded metals which could discolour the surface of the fabricated product. Grain-boundary chromium carbide precipitation for this product will arise by means of having an ensuing very substantial lack of corrosion resistance. The decrease carbon content material on this product minimizes deleterious or dangerous carbide precipitation due to welding. Typical operations for this product encompass bending, forming, and deep drawing and upsetting.