We deliver this product in lots of lengths and widths and might custom reduce on your specific specs. And so, it is devoid of difficulty welded. We deliver this steel in lots of lengths and widths and might custom reduce on your specific specs. This steel gives better creep and pressure rupture properties. This Steel F91 Hollow Bars may additionally be taken into consideration for exposures wherein sensitization and inter-granular corrosion are concerns. In order to offer gold standard resistance to inter-granular corrosion for this steel and to polyphonic acid SCC in provider temperatures at 1500 Degree F – 1650 Degree F, an air cool can be used. This steel is used nearly solely for provider in the sensitizing temperature variety.

This steel is utilized in jet plane additives and oil refinery equipment. The use of a better alloyed filler metallic like this steel may be vital because of the forged shape of the weld metallic. This steel isn't encouraged for positive welding strategies because it isn't consumable. Heat remedy after welding for this steel isn't usually usual. This Alloy Steel F91 Hexagonal Bars is devoid of problems welded through maximum standard processes. This steel reduces susceptibility to inter-granular corrosion. In maximum instances, the carbon content material of this steel allows twin certification.This product is utilized in Expansion joints, Chemical and Petrochemical processing.

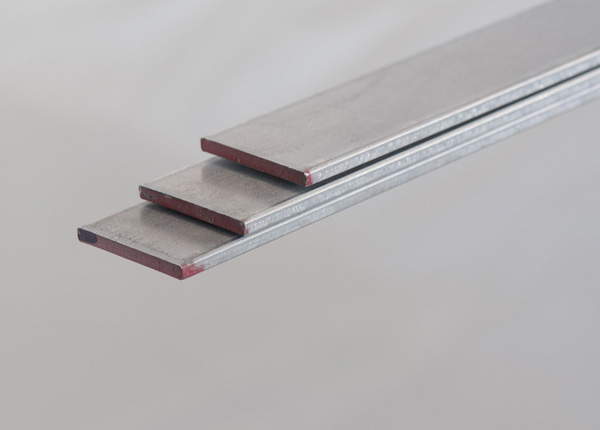

This product is regularly utilized in Jet engine elements and Weld equipment. This product is used drastically for applications wherein the addition of titanium and its stabilizing impact as a carbide forming detail permits it to be welded. This steel is utilized in super-heater and afterburner components.This product is without problems brake or roll formed and has tremendous welding characteristics. This Alloy Steel F91 Triangular Bars has fantastic resistance to inter-granular corrosion after publicity to temperatures within the chromium carbide precipitation variety. This product gives comparable resistance to well-known, basic corrosion because the un-stabilized chromium nickels. This product resists polyphonic acid pressure corrosion cracking.