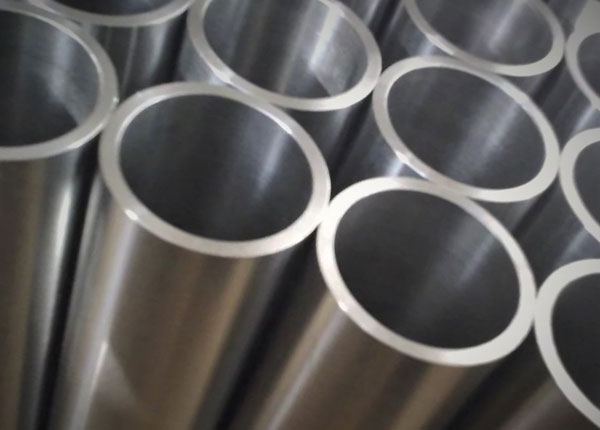

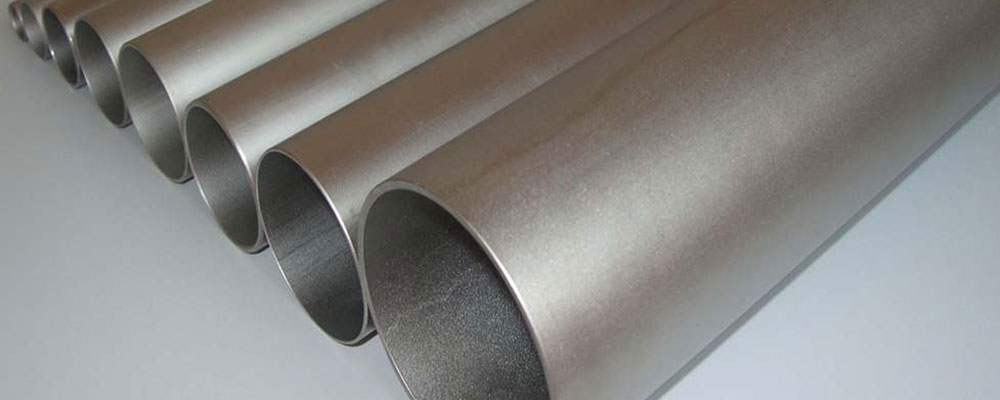

The pleasant corrosion resistance of this product is acquired within the annealed circumstance. Most common cold work techniques are a success in company of this Titanium UNS R50400 Welded Pipes that are to be had at pleasant possible rates. This product is subjected to solution remedy annealing in temperatures starting from 1010 Degree C to 1120 Degree C observed via way of means of speedy cooling. In addition to the annealed circumstance minimal tensile strength, this product is commonly produced in various cold-rolled tempers. This product is an austenitic alloy that shows first rate corrosion resistance properties in company of the added benefits of appropriate strength and ductility while cold worked. Titanium WNR 3.7035 High Pressure Tubes may be readily formed and drawn, and so this alloy additionally has first rate corrosion resistance properties. This alloy is technically a misnomer, however the Chromium within the alloy makes stainless-steel stain much less than not the same metals. This alloy is stabilized grade for heavy segment welding and excessive temperature applications. By means of having a low carbon, this alloy is favoured for progressed ductility or if heavy sections are to be welded, and additionally has a better nitrogen content material to make amends for the decrease carbon.

The susceptibility to carbide precipitation throughout welding restricts the usage of this Grade 2 Titanium EFW Pipes in some applications is used due to its decrease carbon content material for welded applications. Use low facet of variety for intermediate annealing, due to the fact this alloy cannot be hardened via way of means of thermal remedy. This alloy must be understood but that the material may be greater tough to work than poles apart austenitic alloys due its excessive work hardening rate. For intermediate annealing a low temperature variety is chosen, as this alloy is nicely appropriate for welding, forming and drawing.