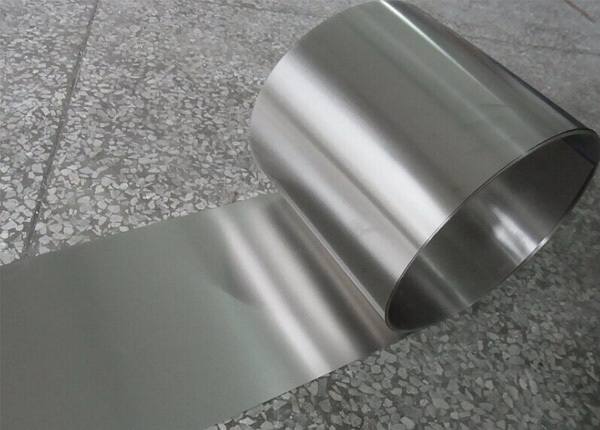

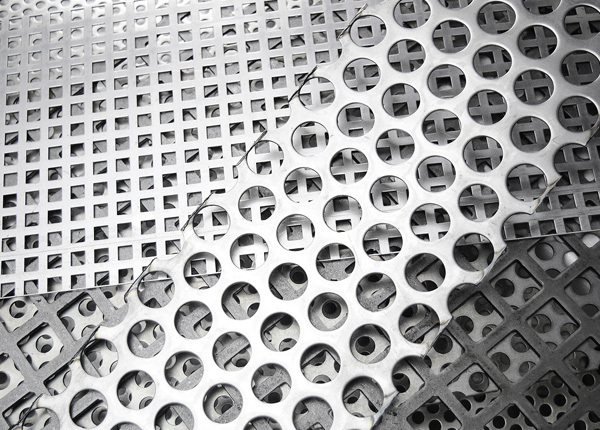

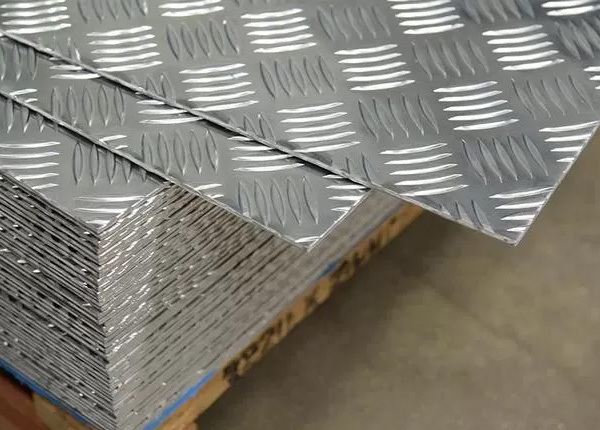

Stainless Steel UNS S31600 Sheets is a solid-solution, strengthened, nickel-chromium-cobalt-molybdenum alloy with an amazing aggregate of excessive-temperature strength and oxidation resistance. The alloy additionally has fantastic resistance to a huge variety of corrosive environments, and it's far readily formed and welded with the aid of using traditional techniques. The excessive nickel and chromium contents make this Stainless Steel WNR 1.4401 Plates proof against lots of each decreasing and oxidizing media. The aluminium, together with the chromium, presents oxidation resistance at excessive temperatures. The resistance of the alloy to excessive-temperature corrosion complements the usefulness of its strength.The aggregate of excessive strength and oxidation resistance at temperatures over 1800 Degree F (980 Degree C) makes this Stainless Steel UNS S31603 Sheets an attractive material for such additives as ducting, combustion cans, and transition liners in each plane and land-based gas generators. Solid-solution strengthening is imparted with the aid of using the cobalt and molybdenum.

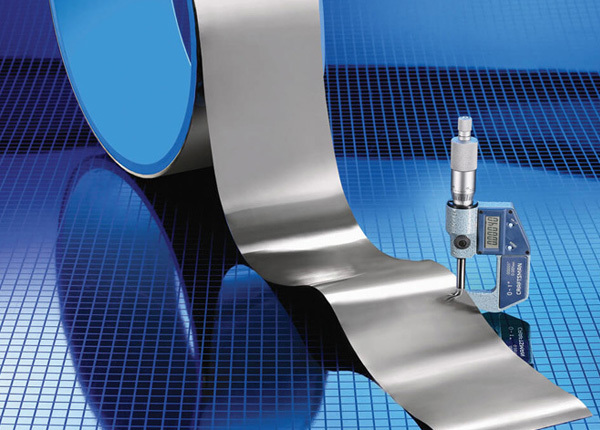

The low density of Stainless Steel WNR 1.4404 Plates, in comparison with tungsten-containing alloys of similar strength, is enormous in applications along with plane gas generators wherein excessive strength-to-weight ratio is desirable. Values for thermal conductivity and specific heat have been calculated; different values have been measured. Thermal enlargement of this Stainless Steel UNS S31635 Sheets is decrease than that of maximum different austenitic alloys, decreasing stresses from differential enlargement whilst the alloy is coupled with carbon steels or low-alloy steels. It has excessive mechanical properties over an extensive variety of temperatures. The improvement of this Stainless Steel WNR 1.4571Platesis focused at the choice for max creep strength at accelerated temperatures.Because of its resistance to excessive-temperature corrosion, the alloy is used for catalyst-grid helps within the manufacturing of nitric acid, for heat-treating baskets, and for discount vessels within the refining of molybdenum.