These Nickel UNS N02200 Olets have very tough mechanical properties which create boundaries for traditional machining. The very properties that offer the perfect excessive-temperature properties can restriction the ability to shape a chip in a milling or turning operation. This is due in element to mechanical and structural abnormalities—those alloys can seem brittle or tender at times, posing diverse machining problems. The biggest marketplace is industrial jet engines; however different comparable usages are in sun thermal energy plants, heavy-duty heat exchangers, corrosive commercial environments, and rocket engines. Many layout engineers are searching for to remove the use of these Nickel WNR 2.4066 Olets for the reason that of their costs – mainly the producing and supply costs. However, making use of strategies consisting of pulsed electrochemical machining can power down costs, allowing the use of those alloys in applications which have been formerly cost prohibitive with traditional machining techniques. Researchers are continuously searching for to broaden new alloys with an excellent better resistance temperature, as commercial wishes for fueloline mills and heat exchangers increases. Better processing strategies are yielding purer alloys, and researchers are more and more introducing refractory factors like Tungsten and Molybdenum.

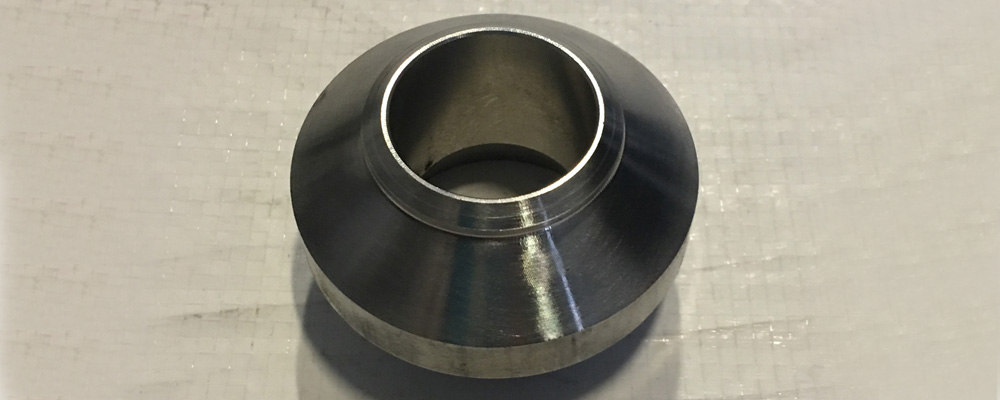

As the abilities and applications of those precise alloys are advanced, maximum traditional machining techniques may be not able to competently in shape the extended expectancies of machining superalloys. Ni-200 Olets is firstly advanced for potential application in supercritical (very excessive temperature) steam energy plants. The alloy composition is predominantly a nickel-chrome base that means it's far immune to oxidation at improved temperatures. However, the addition of Nb, Ti, Al and Ni shape a chain of precipitates at some point of the controlled solution annealing and getting old method steps, ensuing in a great growth in strength and hardness in comparison with opportunity nickel alloys. Therefore, on the spot target applications protected fasteners, valve gates, seats, stems and trim.